AUTONOMATION

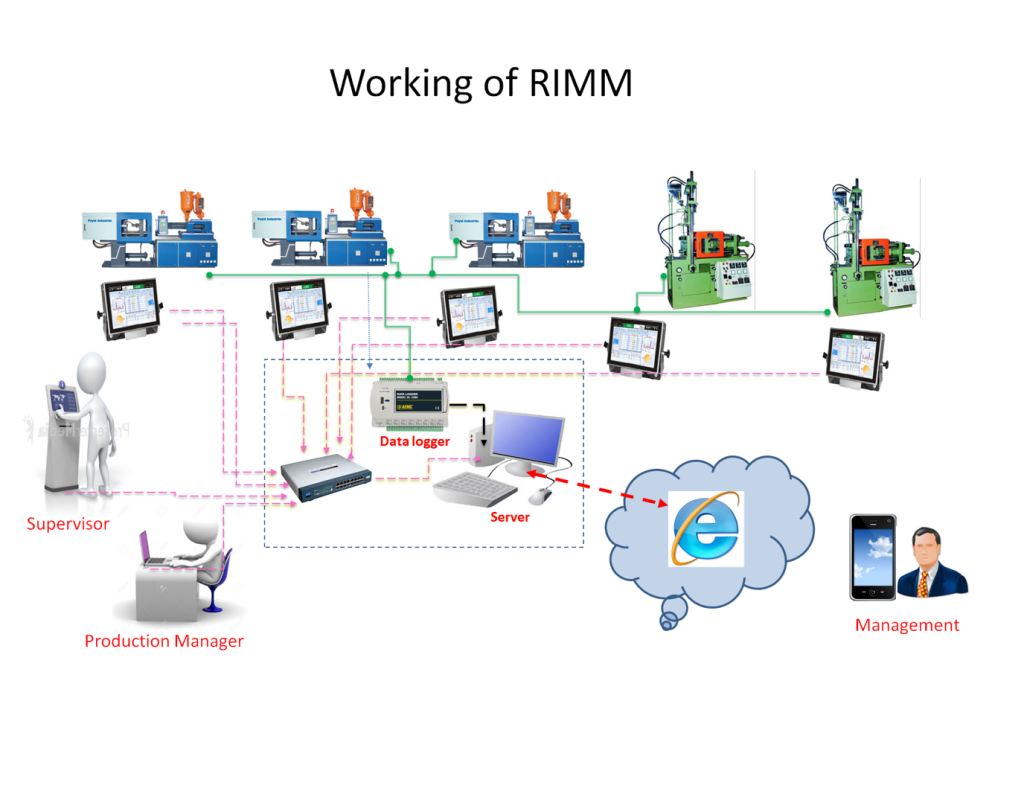

Connecting

Data on Finger tips

We are taking digital manufacturing to the next level where your shop floor now fits in the palm of your hands. No matter where you go or where you are and how big your plant is, you are just a click or touch away. This complete and superior controls enables you to excel in your business without having to worry about uncertainties on the shop floor.

INDUSTRY 4.0

Our Software Supports to INDUSTRY 4.0.

MACHINE INDUSTRY

Our Software works for Machine Industry.

IOT BASED SOLUTIONS

Our Software provides IOT Based Solutions.

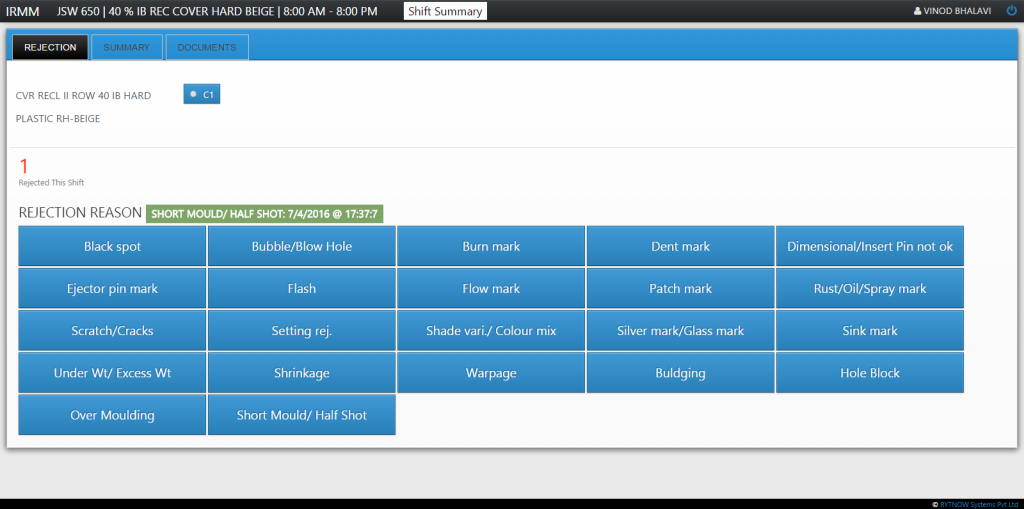

Quality Manager

- Spread awareness regarding defects and its type easily

- Monitor the rejections online

- Instant analysis and reporting of defects

- No more documents to be pasted on the machine

- No more manual paper based sharing and storage

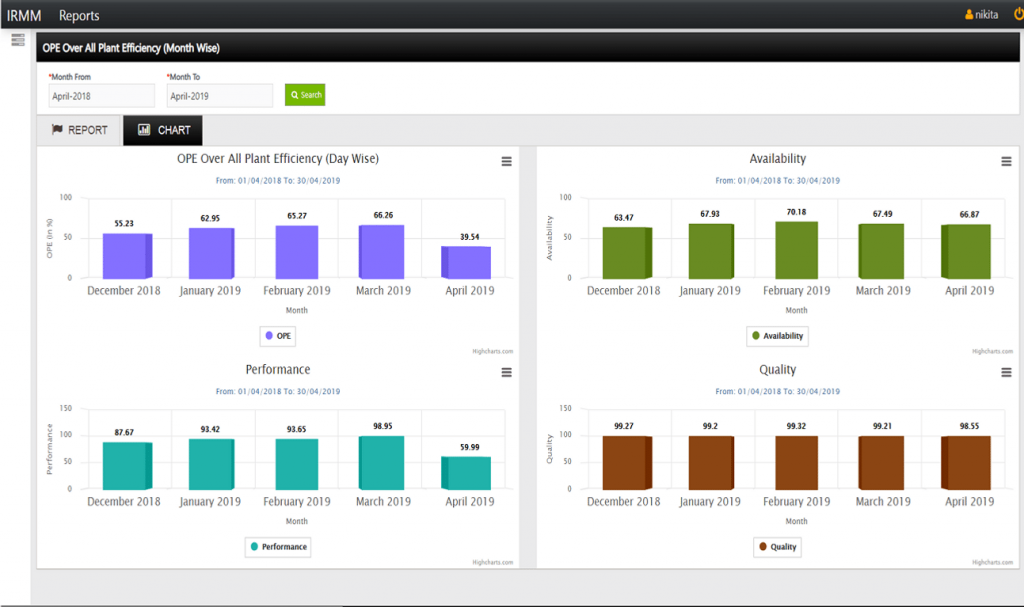

PRODUCTION MANAGER

- Dashboard facility to monitor the shop-floor online

- Live tracking of Production targets

- Planning for resources and manpower easier

- Hourly, Shift wise, monthly production data available for analysis

- live data retrieval for daily meetings

- All historical production data available on shop-floor at a click

- Tracking on down times through OEE, OPE, breakdown & etc reports

- Different reports related to customer complaint for analysis purpose

- No more manual paper based sharing and storage

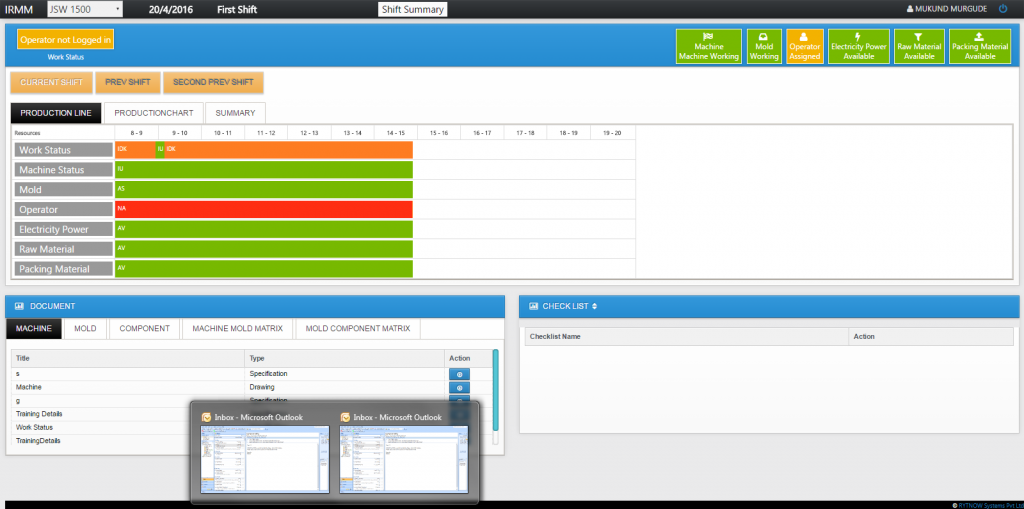

SUPERVISOR

- Automatic Production, Rejections summary for every machine

- Live Tracking & Reporting of Downtime along with Reason

- Hour-wise production summary along with benchmark compare

- All Quality & Production documents available online at Machine

- Accurate & Easy Shift Closure & Reporting

- Rich Graphic User Interface for quick grasping of issues

- No more manual paper based sharing and storage

OPERATOR

- Online Documents for reference

- Live Production Logging

- Online Rejection feeding

- Live summary of Production & Rejection

- Ownership of the machine

- Accurate Rejection entries

- No more manual paper based sharing and storage

OUR QUALITIES

Connecting Key Points

Glance at Our Organizational core values